In today’s packaging industry, where flexibility and reliability make the difference, one of the world’s leading ketchup producers turned to Zambelli Packaging to tackle a high-level production challenge: developing a line capable of packaging elliptical-shaped bottles at high speed, across multiple formats and pack types—without sacrificing efficiency or process stability.

The goal: packaging shaped ketchup bottles at up to 20,000 bottles/hour

The project involved the design and supply of a robotic secondary packaging line, engineered to:

- Handle 5 different sizes of unstable, non-accumulable elliptical bottles

- Process 12 distinct secondary packaging configurations, including wrap-around packs and high-wall trays

- Maintain a line speed of up to 20,000 bottles/hour, with peaks of 60 cartons/minute

One of the biggest challenges was the elliptical bottle shape, commonly used for ketchup and mayonnaise. These bottles tend to rotate and jam traditional packaging systems. Classic automation alone wasn’t enough—a robotic approach was essential.

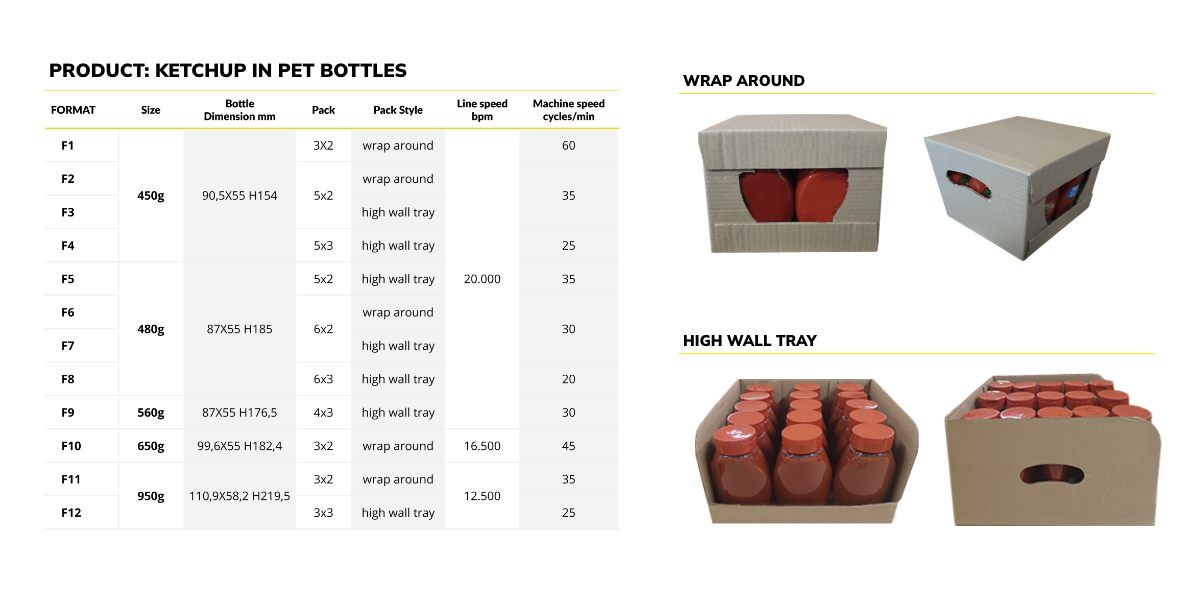

12 formats: PET bottles ranging from 450 g to 950 g across 12 pack styles

The following chart details the formats and configurations handled by the Zambelli line:

Zambelli Packaging answer: a high-flexibility robotic case packer

To meet this complex requirement, Zambelli Packaging developed a robotic case packer designed to:

- Easily handle unstable bottles with a pick & place system equipped with five interchangeable robotic heads, switched out quickly and automatically

- Form three cartons per machine cycle, achieving speeds up to 60 cycles/minute

- Rotate and position bottles precisely using intelligent screw feeders (coclee)

- Close lids automatically with integrated flap management

- Perform fully automated format changeovers, requiring no manual intervention

- Operate with synchronized transport across forming, filling, and closing phases

Key benefits: accuracy, modularity & energy savings

🔧 Modularity: Each section of the line is scalable and reconfigurable, ready to adapt to new SKUs in the future.

⏱️ Fast format change: No downtime—maximized OEE (Overall Equipment Effectiveness).

🌍 Energy efficiency: Powered by brushless motors, with optimized motion and reduced packaging materials.

See the line in action

Discover how our robotic case packer handles shaped bottles with precision and speed: Watch the video 👇

📩 Do you have a similar challenge at your plant?

Our team is ready to work with you to develop the next generation of customised case packers.

📩 Contact us for personalised technical advice: contact@zambelli.it