In the ever-evolving world of secondary packaging, the customization of automatic machines and the optimization of their production efficiency are two crucial aspects that can make a company more or less competitive within its target market.

For this reason, we at Zambelli Packaging are committed to providing cutting-edge machinery that meets the diverse needs of our customers, and more! We actively contribute to the success of production lines by designing high-level machines that can be further implemented. The performance achieved by our Shrink Wrapping and Case Packing machines reflects today's needs: greater autonomy, time savings for operators on the line, energy savings, flexibility and ease of use.

In today's article, we will share the key features of our packaging machines, starting from the accessories and special groups dedicated to customizing your lines, up to the premium features that can further enhance the already excellent performance of Zambelli Packaging machines.

Special Groups and Accessories for Zambelli Packaging Shrink Wrappers

The Zambelli Packaging Shrink Wrappers are designed to meet the highest standards of efficiency and customization.

These essential characteristics ensure that our machines provide optimal performance, energy savings and adaptability to various packaging needs.

Now we’ll highlight the core features of our shrink wrapping machines, showcasing the special groups and accessories that enhance their functionality and meet your specific packaging requirements.

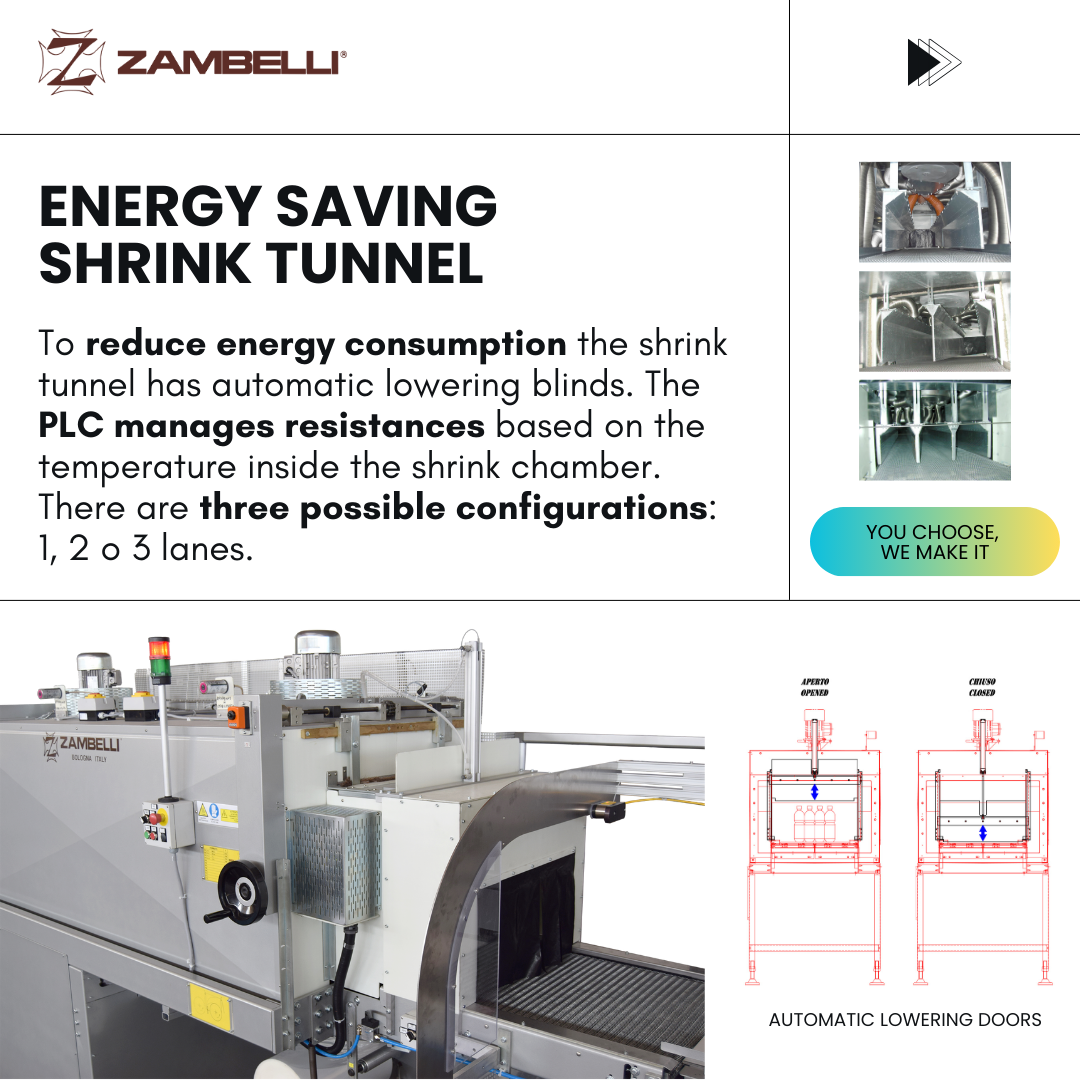

Energy Saving Shrink Tunnel

- To reduce energy consumption and quickly reach the temperature "set point" at machine startup, the shrink tunnel has automatically lowering blinds at the entrance and exit.

- To let customers, and the environment, truly benefit from the small gauge films now available, Zambelli has fitted its shrink tunnels with analogic relays on the lower heating coils. This feature allows to fine tune the heating power saving energy and achieving an optimal shrink and seal.

- Pre-installed spare resistances prevent machine downtime.

- The machine offers three possible configurations (1, 2, or 3 lanes) for lap seal shrink wrappers and one lane for sealing bar shrink wrappers.

- An effective cooling section at the tunnel exit ensures packs have stabilized when leaving the machine.

- By means of external handwheels air flow inside the tunnel can be optimized even for packs of very different sizes.

- A pneumatic motor empties the shrink tunnel in case of a blackout.

Magazines

In addition to film-only, our shrink wrappers can package with Flat Pad & Film or with Tray & Film.

To these configurations perforated lids can be added to stabilize tapered bottles during film shrink or side cardboard inserts (flat or "C" shaped) to prevent jars from falling out of display trays low front wall.

Dedicated magazines can be added to the machine for these cardboard inserts.

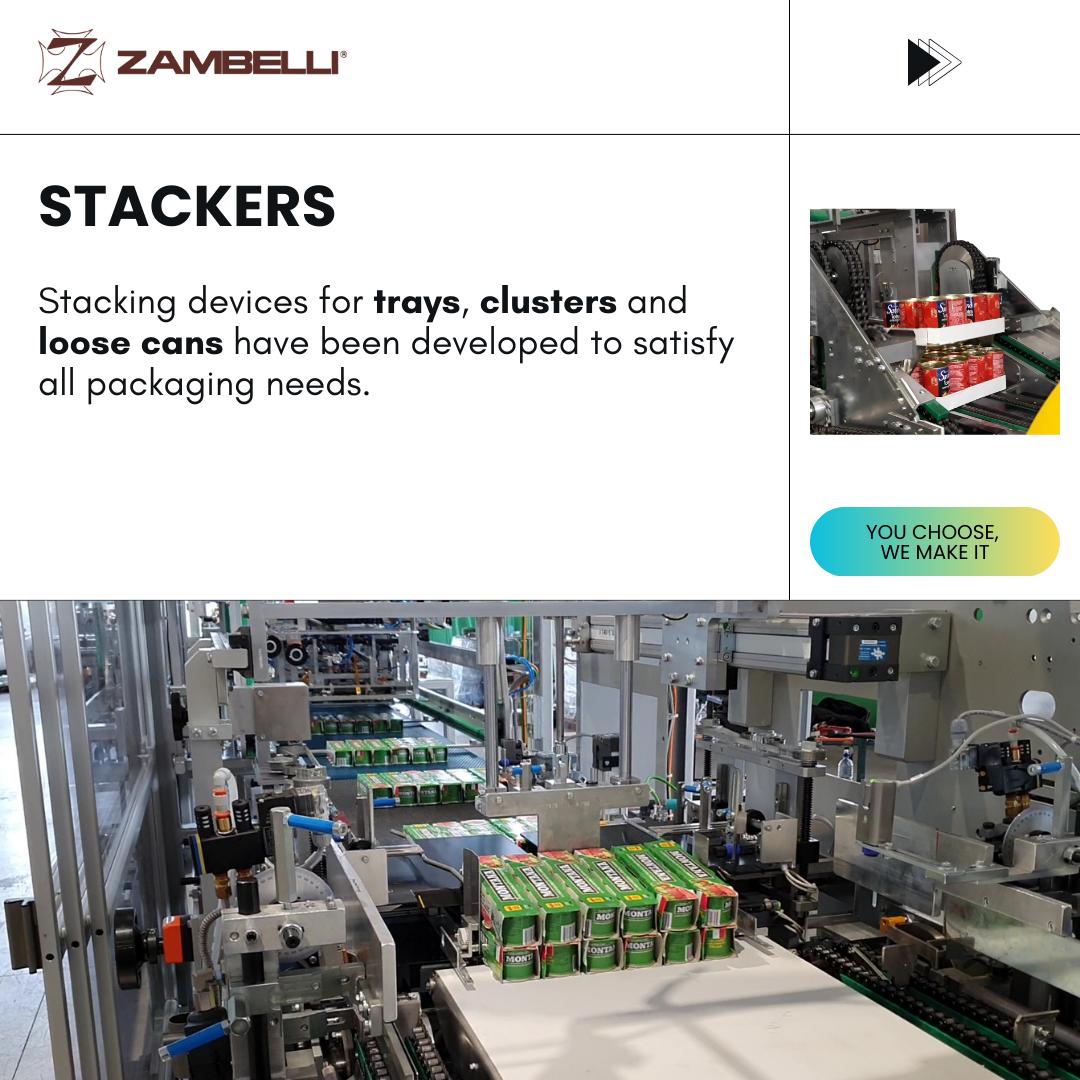

Stackers

Stacking devices for trays, clusters and loose cans have been developed to satisfy all packaging needs.

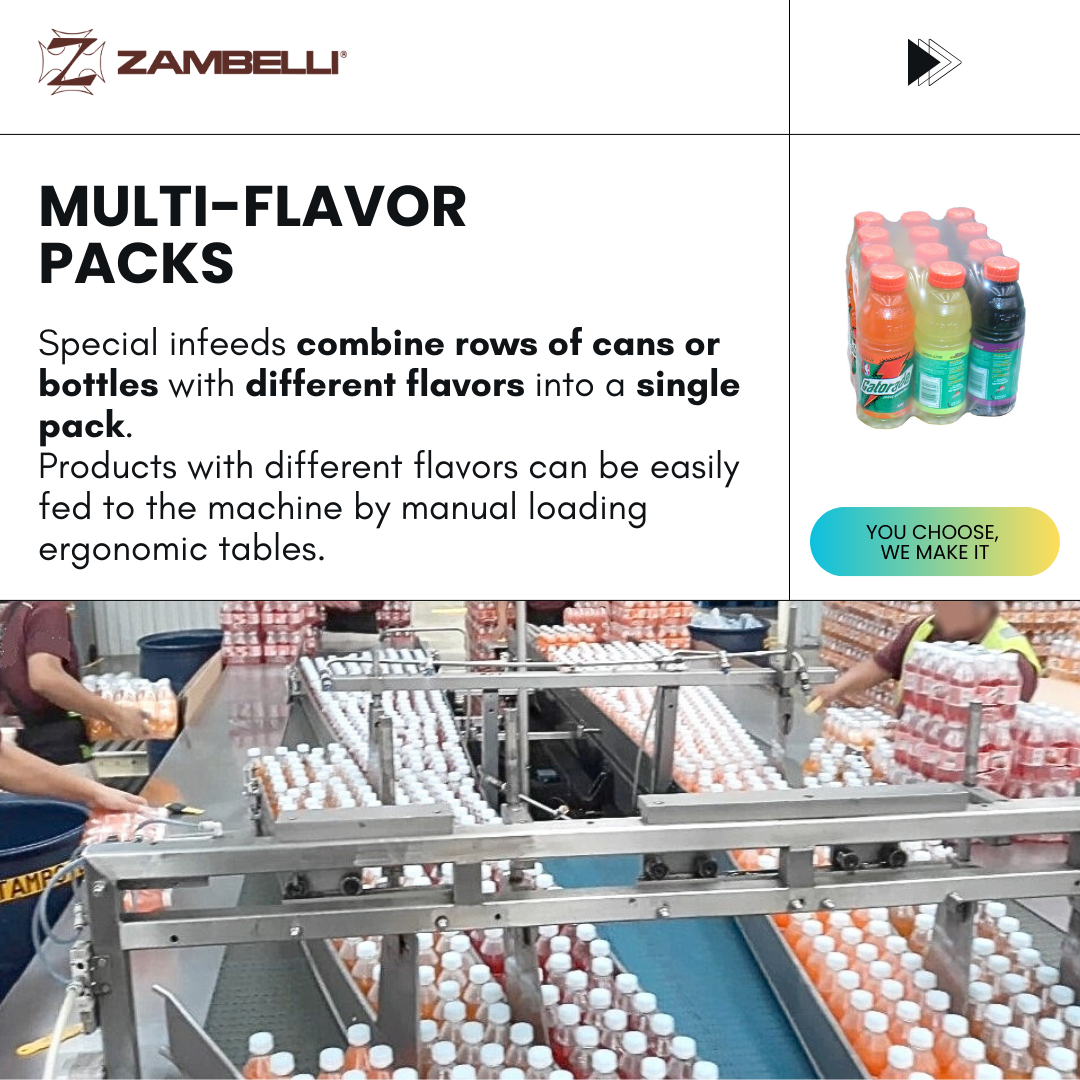

Multi-Flavor Packs

Special infeeds combine rows of cans or bottles with different flavors into a single pack.

Products with different flavors can be easily fed to the machine by manual loading ergonomic tables.

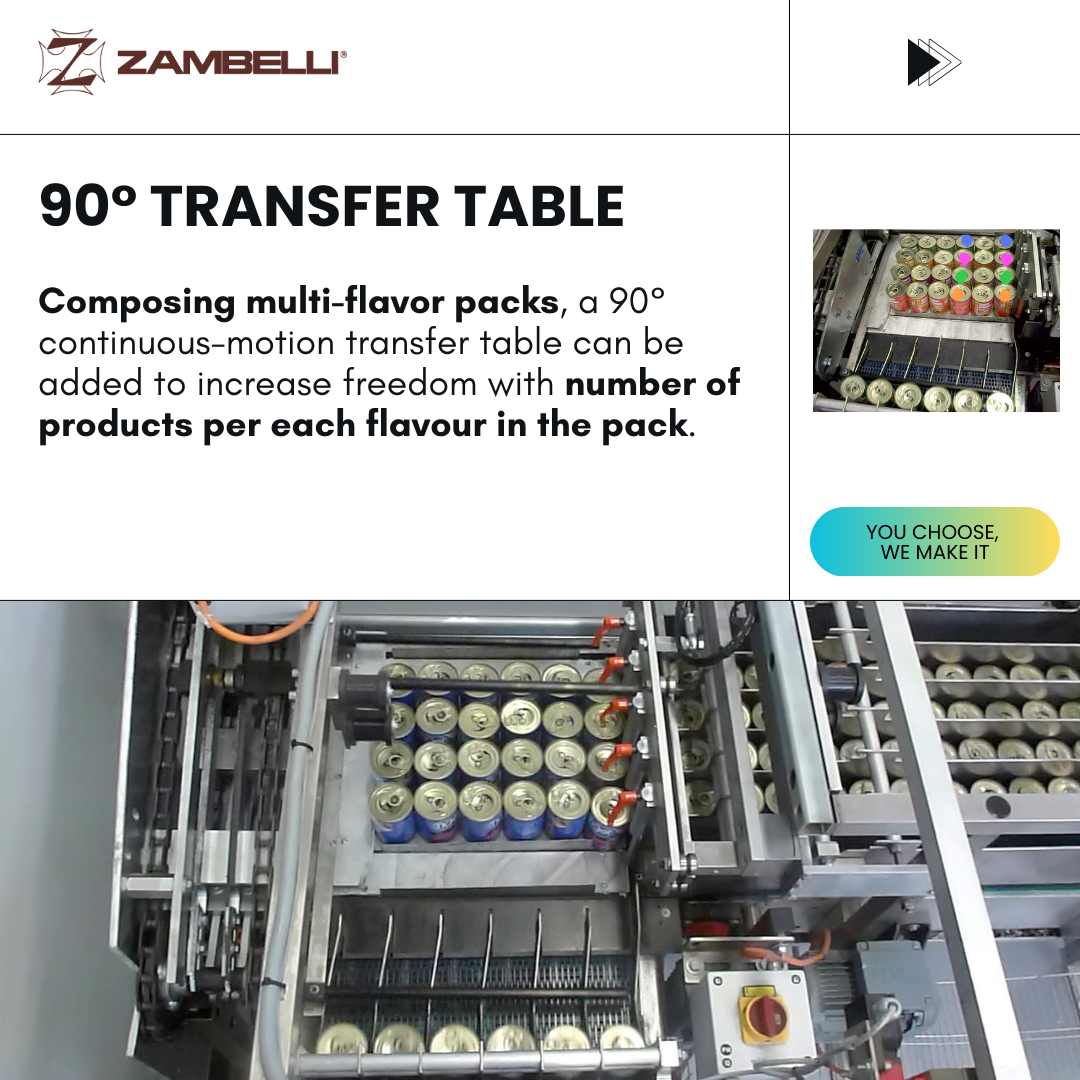

90° Transfer Table

Composing multi-flavor packs, a 90° continuous-motion transfer table can be added to increase freedom with number of products per each flavour in the pack.

Automation Components & Motors Customization

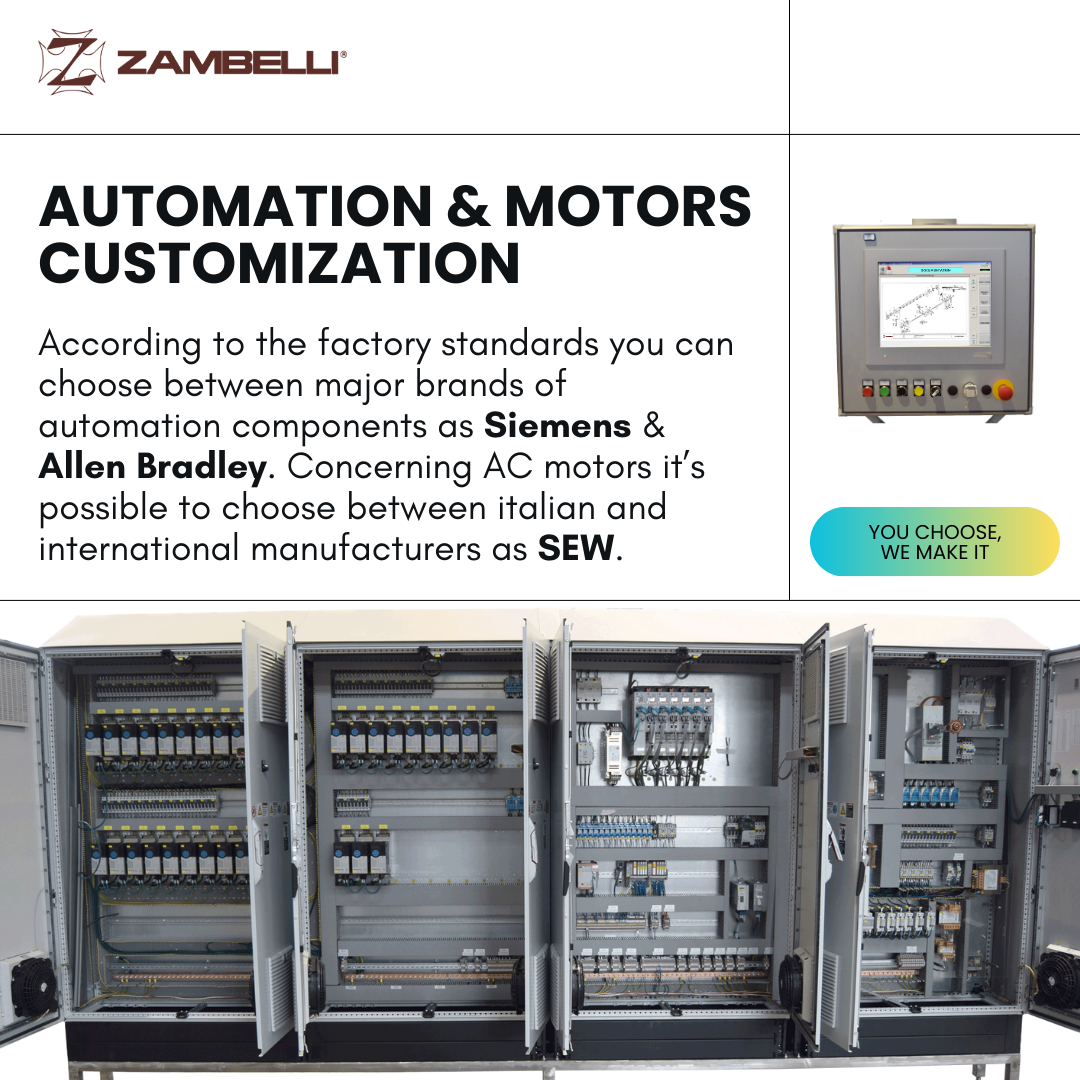

According to your factory standard, you can choose between major brands of automation components as Siemens or Allen Bradley for PLC, HMI, servomotors, servodrivers, and inverters.

Concerning AC motors it is possible to choose between italian or international manufacturers as SEW.

These customizable features are designed to provide you with the flexibility and efficiency needed in today’s competitive packaging industry.

Transform your packaging operations!

Find the perfect Shrink Wrapper tailored to your needs.

Request a free consultation and discover how we can help streamline your packaging process!

Premium Features for Zambelli Packaging Shrink Wrappers

Do you want to elevate your packaging efficiency?

You need our Shrink Wrappers premium enhancements.

In today's fast-paced packaging industry, efficiency and flexibility are crucial. Our shrink wrappers offer a range of premium features that can significantly boost performance and ease of use. These features can be chosen according to your specific needs to optimize machine functionality and efficiency.

Here are the key premium features available for our shrink wrappers:

Automatic Film Splicing

The shrink wrapping machine has two film holders; one holds the working film reel, and the other a spare reel ready for use. Just before the reel ends, the machine stops to allow manual film splicing. With this optional feature splicing is automatic, without affecting printed film registration and giving operator more time to manage their tasks.

Printed Film Registration

Printed film is a powerful marketing tool to make customer choose your product. It requires your logo and message to be perfectly placed on the pack’s face. Our print registration option includes sensor and software to keep your logo exactly as desired at any machine speed.

Integrated Pre-Shrink Tunnel Handle Applicator

In the consumer goods market the handle on the shrink pack gives your product a competitive edge. Instead of a stand-alone handle applicator, Zambelli Packaging offers as an option the pre-shrink-tunnel handle applicator integrated within the machine.

90° Cluster Rotation System

Cluster packs move on conveyors with short side leading. This creates a constrain on pack collations. The Zambelli Packaging optional 90° cluster rotation system turns the packs with the long side leading, creating a pack that is easier to handle.

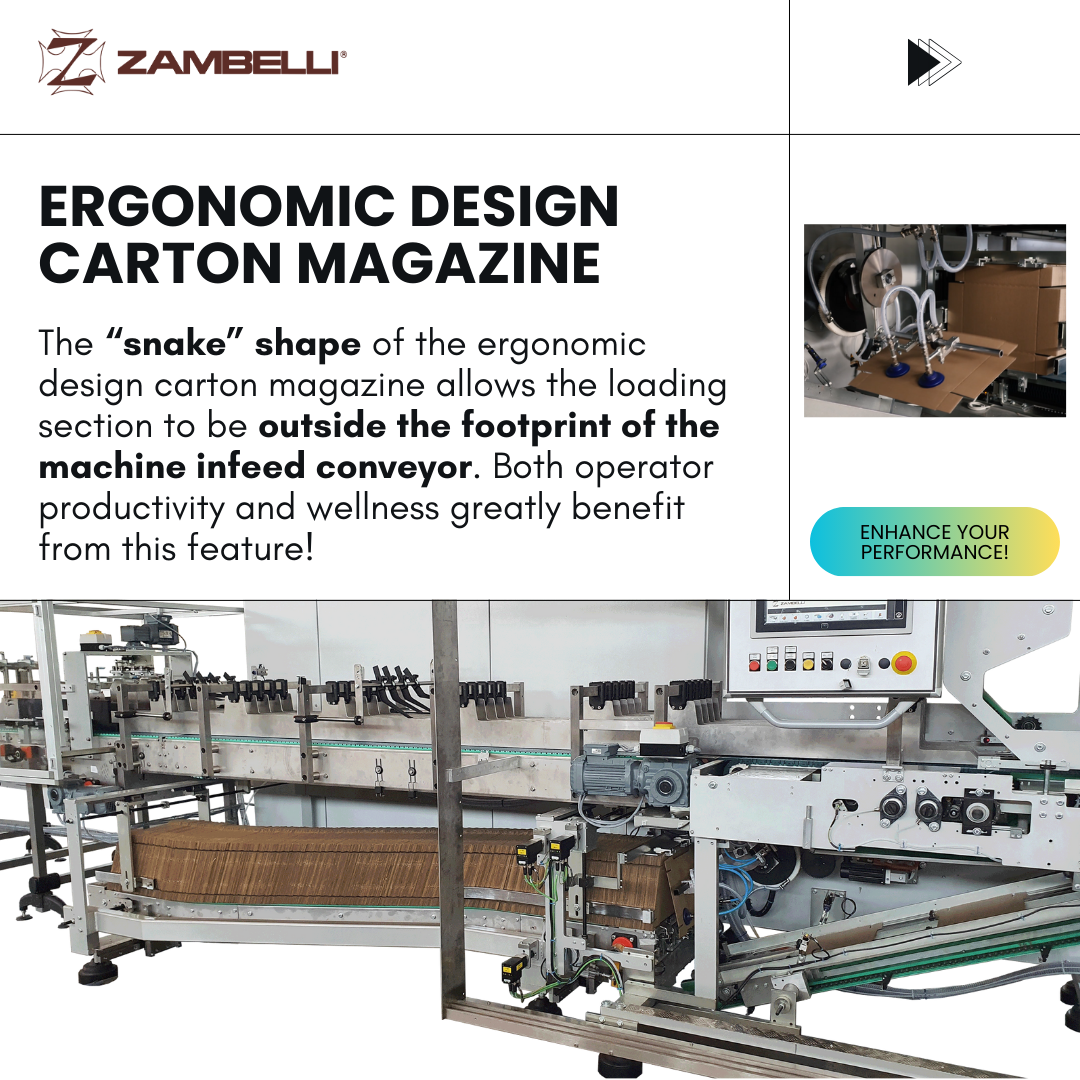

Ergonomic Design Carton Magazine

Loading cartons onto the magazine can be made easier for the operator by the ergonomic design carton magazine. Its “snake” shape allows the loading section to be outside the footprint of the machine infeed conveyor.

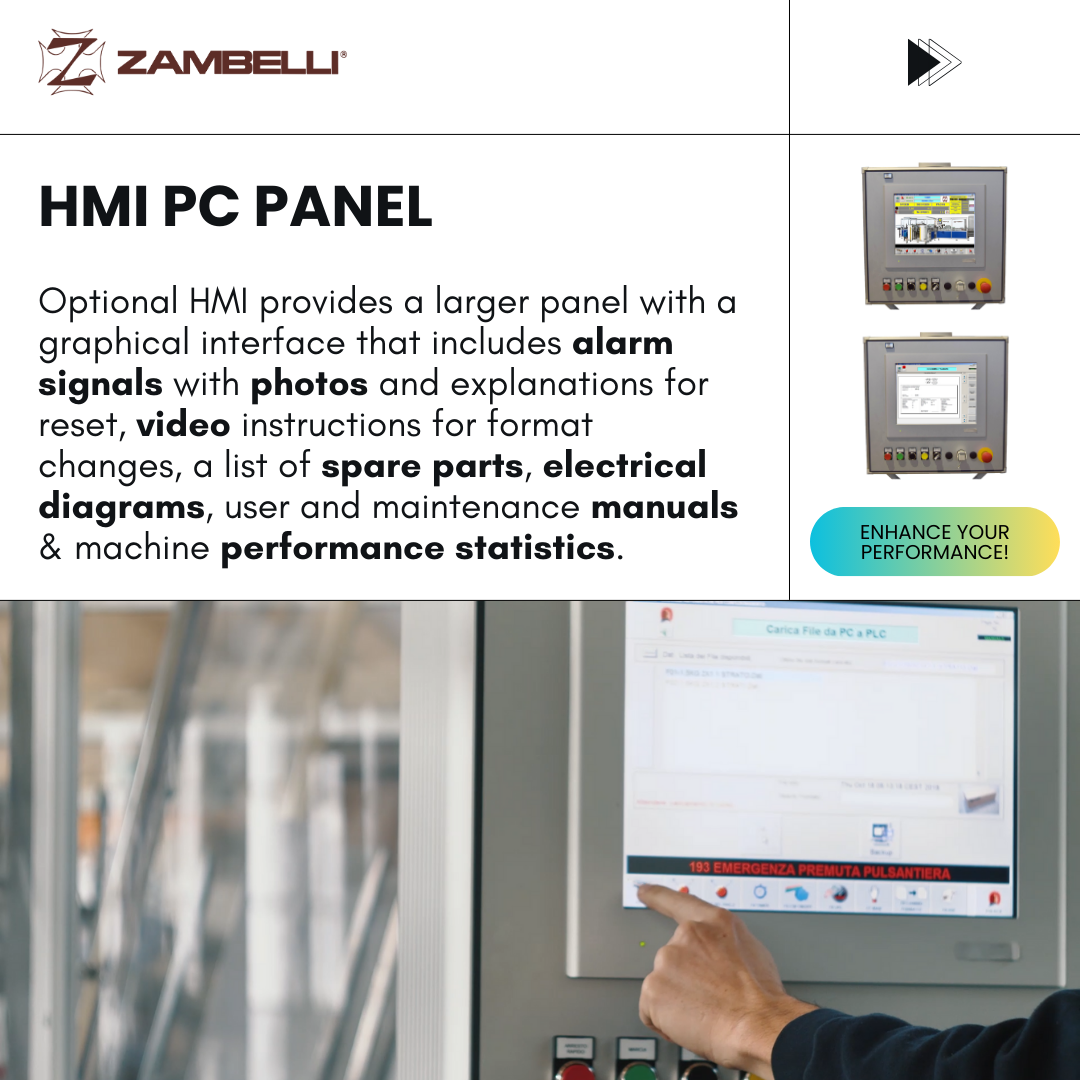

HMI PC Panel

The optional HMI provides a larger display with a graphical interface that includes photos and explanations for alarm reset and troubleshooting, video tutorials on format change-over, a list of recommended spare parts, electrical diagrams, user and maintenance manuals as well as machine performance statistics.

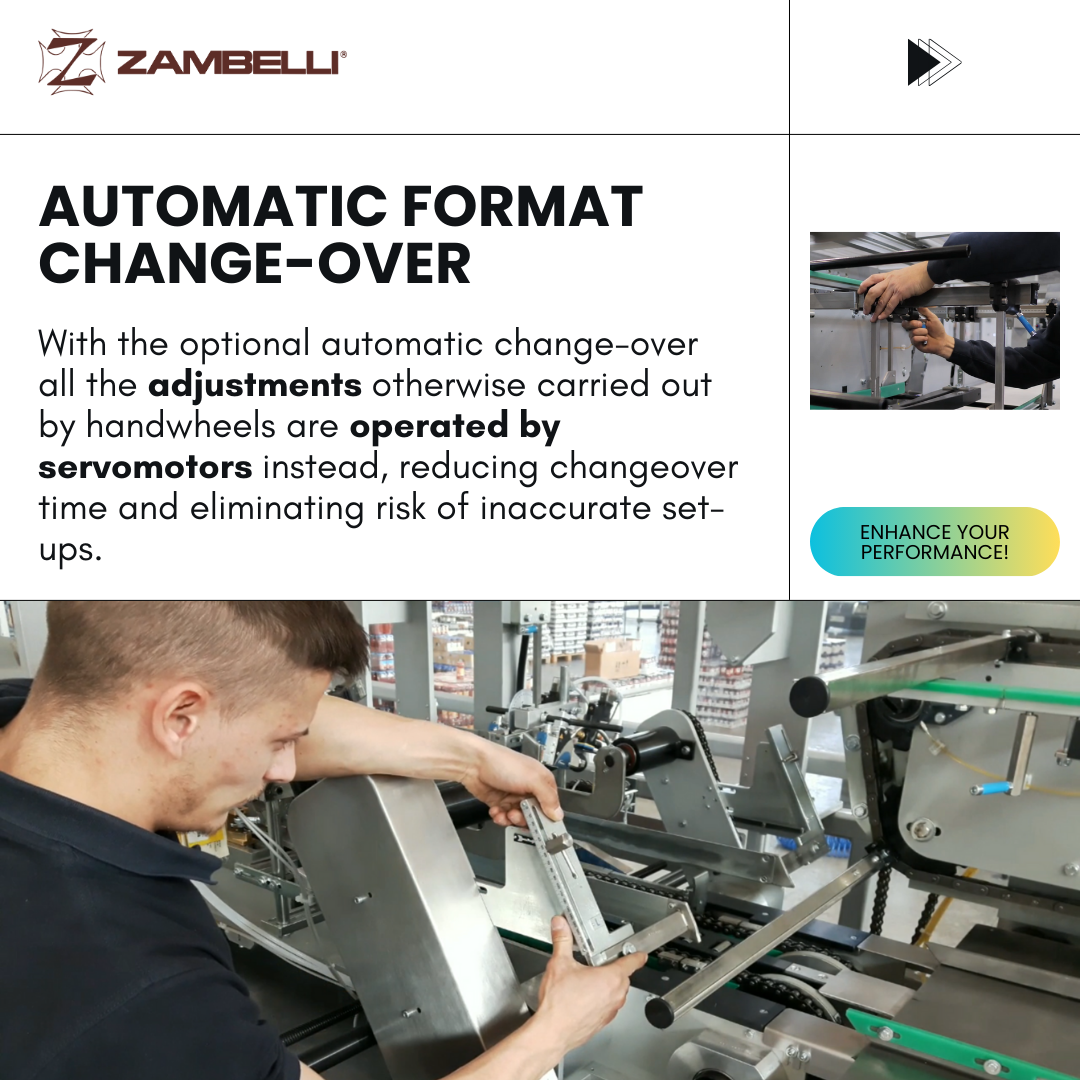

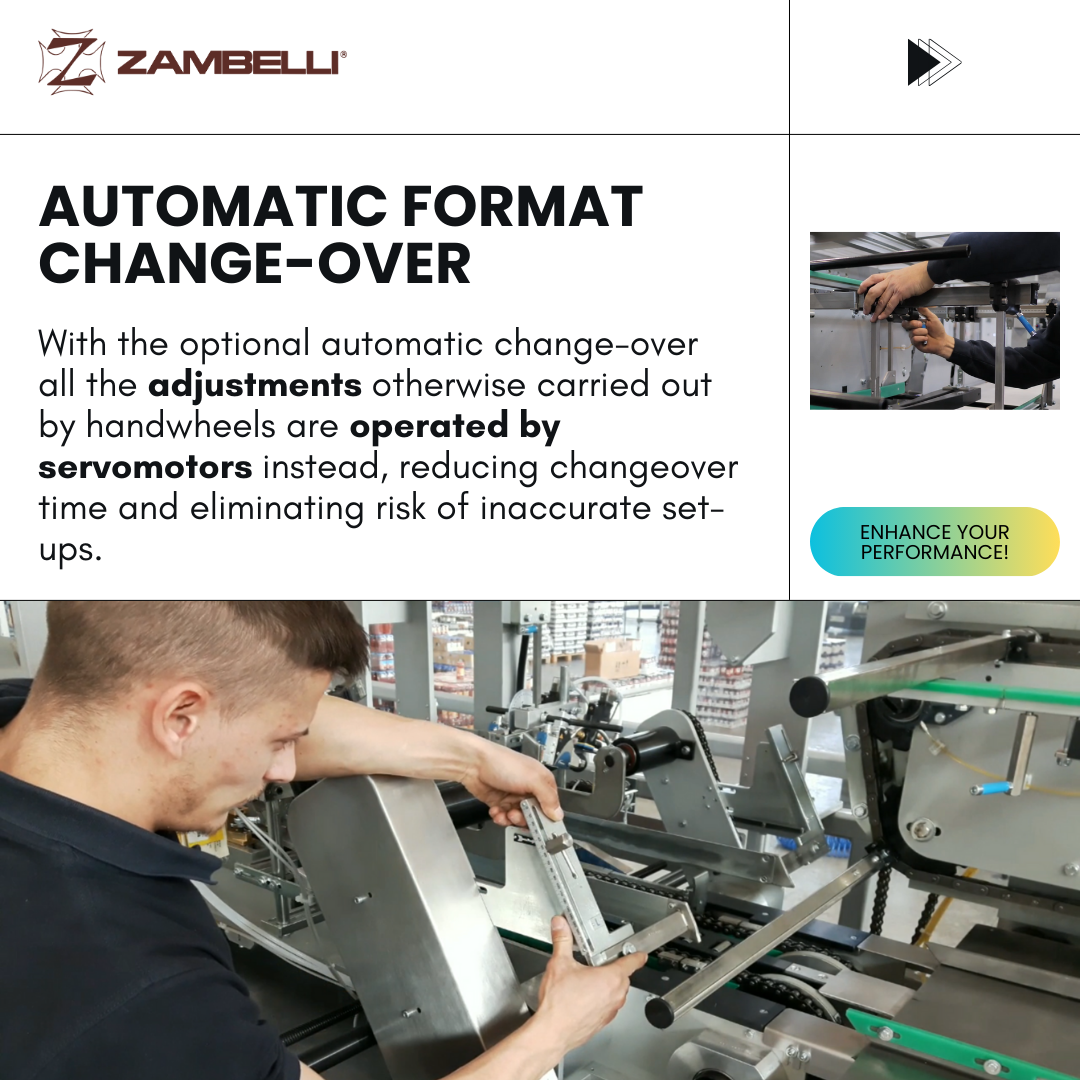

Automatic Format Change-Over

With the optional automatic change-over all the adjustments otherwise carried out by handwheels are operated by servomotors instead, reducing changeover time and eliminating risk of inaccurate set-ups.

Automatic Lubrication

The optional version includes a PLC-controlled pump that performs programmable lubrication without maintenance personnel’s intervention.

By selecting these optional features, you can tailor your shrink wrapper to meet your specific needs, enhancing overall productivity and operational efficiency, delivering superior results.

Enhance your packaging efficiency!

Let us assist you in selecting the best shrink wrapper machine for your production line.

Request a free consultation now and take the first step towards optimized packaging!

Special Groups and Accessories for Zambelli Packaging Case Packers

At Zambelli Packaging, we are committed to provide top-tier solutions for your secondary packaging needs. Our case packers are designed to be flexible and customizable, ensuring that you can meet any packaging requirement with ease.

Here's a closer look at some of the key and customizable features that make our case packing machines stand out:

Case Forming

Our case packers are available with either a single magazine for RSC American Case or Wrap-Around Case, or a dual-magazine system designed for tray and lid packaging.

The lid can be placed either inside the tray or externally, according to your needs.

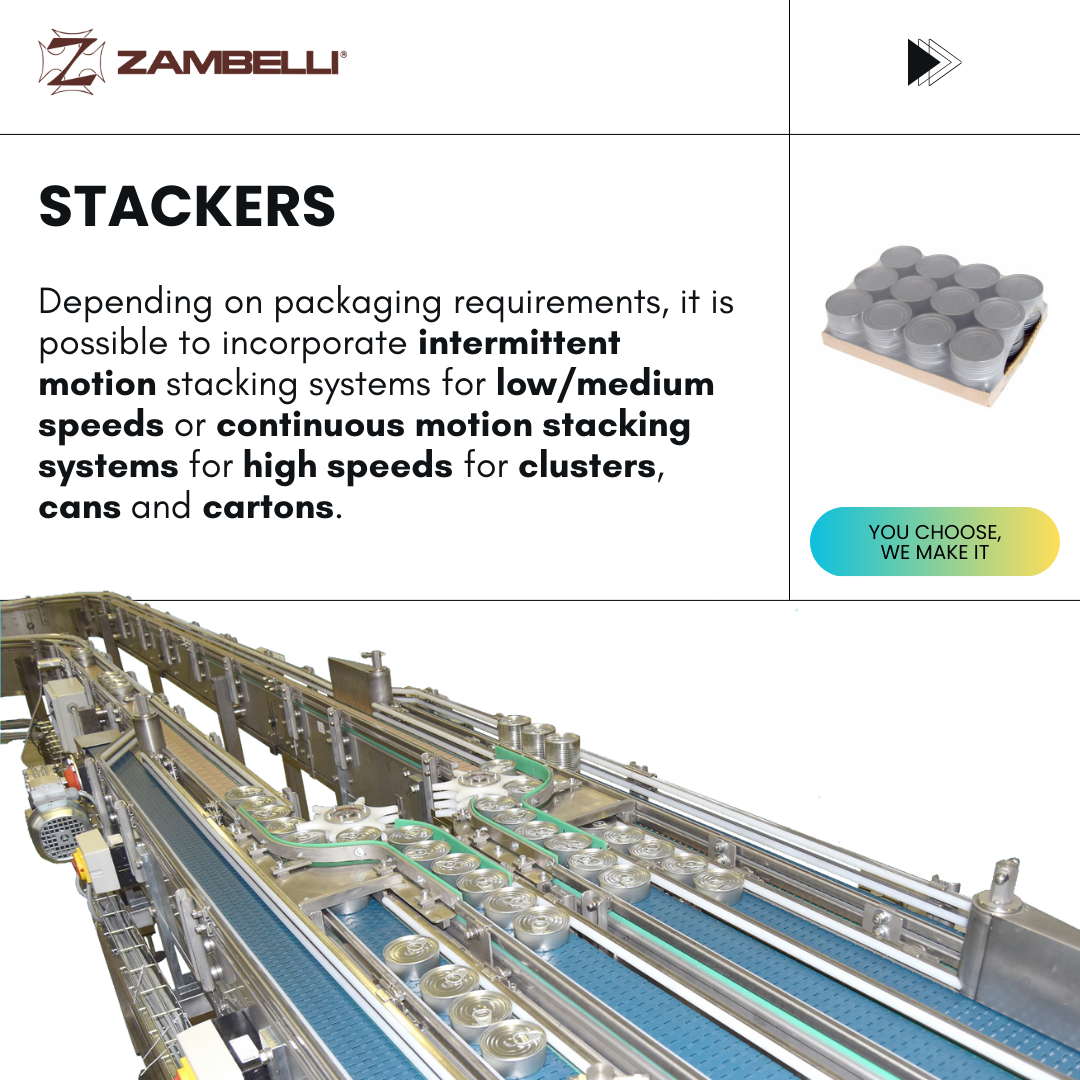

Stackers

To meet various packaging requirements, our machines can be equipped with stacking systems.

Choose between intermittent motion stackers for low/medium speed or continuous motion stackers for high speed, both suitable for clusters, cans, and cartons.

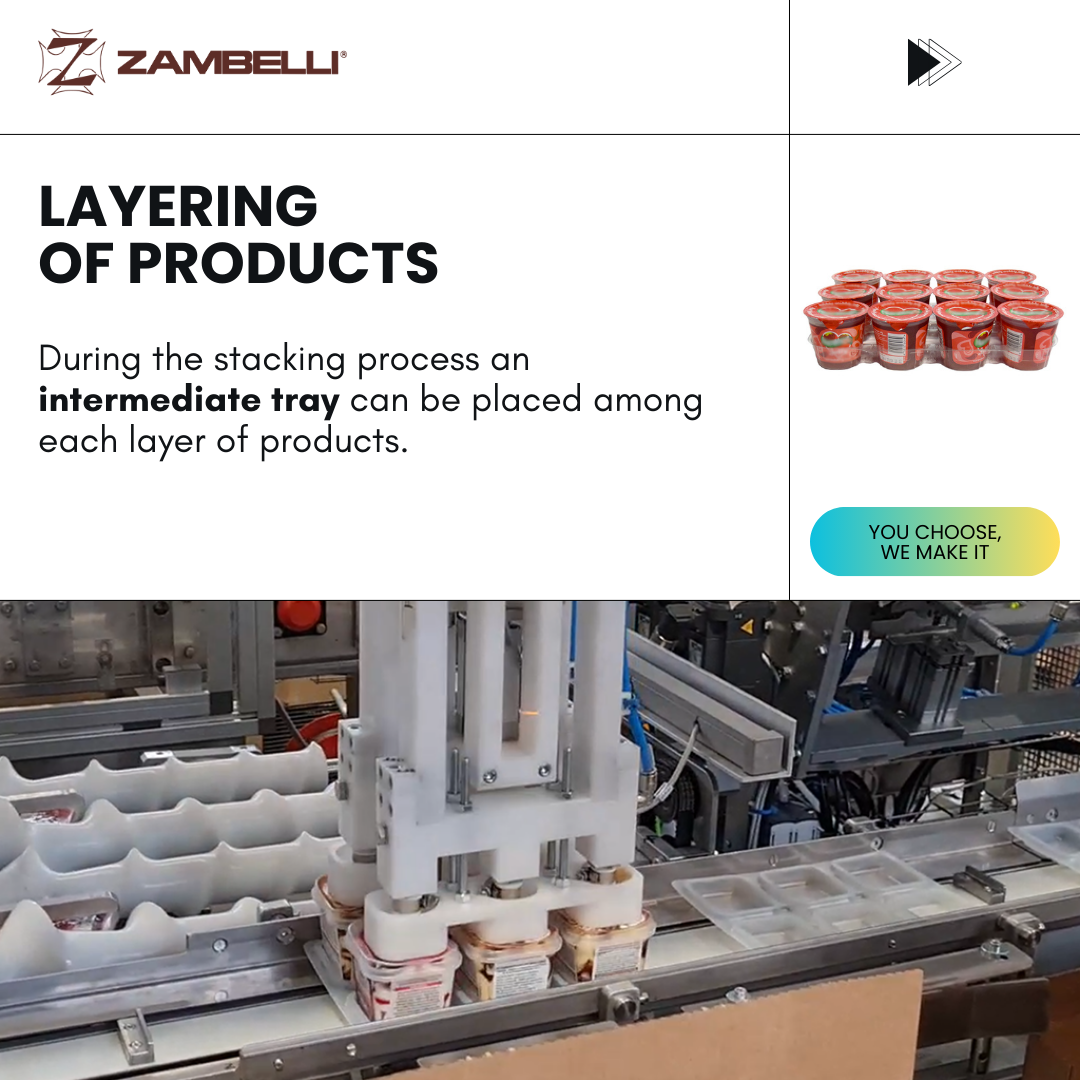

Layering of Products

During the stacking action an intermediate tray can be placed among each layer of products.

Automation Components & Motors Customization

According to your factory standard, you can choose between major brands of automation components as Siemens or Allen Bradley for PLC, HMI, servomotors, servodrivers, and inverters.

Concerning AC motors it is possible to choose between italian or international manufacturers as SEW.

Hot Melt Unit Customization

We can integrate a variety of hot melt unit brands, including Preo, Nordson, and Robatech, allowing you to match your factory standard.

By prioritizing flexibility and customization in our design, we can offer efficient, reliable and high-quality packaging solutions.

Transform your packaging operations!

Find the perfect Case Packer tailored to your needs.

Request a free consultation and discover how we can help streamline your packaging process!

Premium Features for Zambelli Packaging Case Packers

As with shrink wrapping machines, case packers can also be upgraded with premium features to increase their automation and make them even more user-friendly.

These enhancements are designed to provide greater autonomy, streamline operations and reduce manual interventions, ensuring that your packaging process is as efficient and effective as possible.

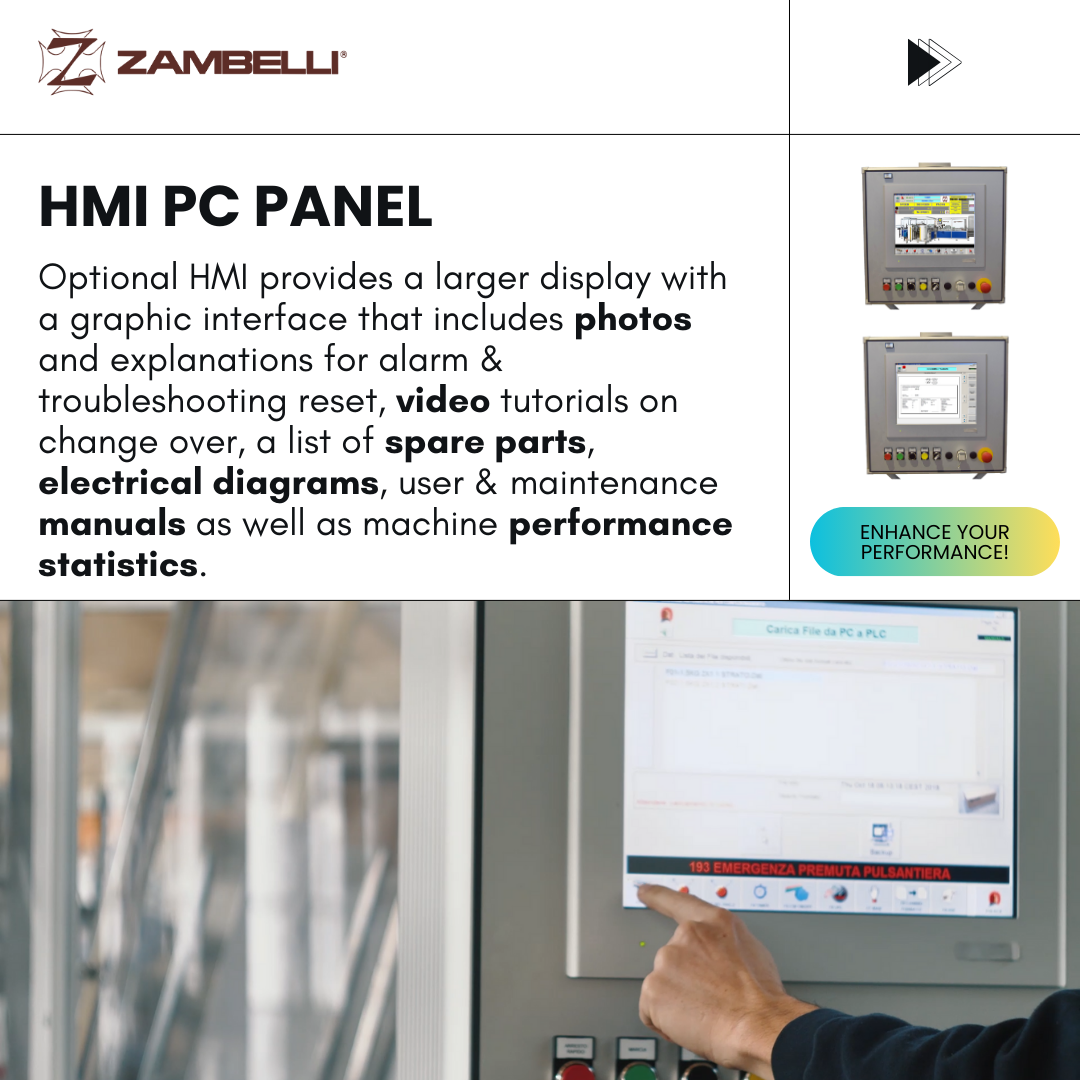

HMI PC Panel

The standard panel is compact and fitted with a text-based interface, allowing complete machine management through its available operations.

Opting for the optional HMI provides a larger display with a graphical interface that includes photos and explanations for alarm reset and troubleshooting, video tutorials on format change-over, a list of recommended spare parts, electrical diagrams, user and maintenance manuals as well as machine performance statistics.

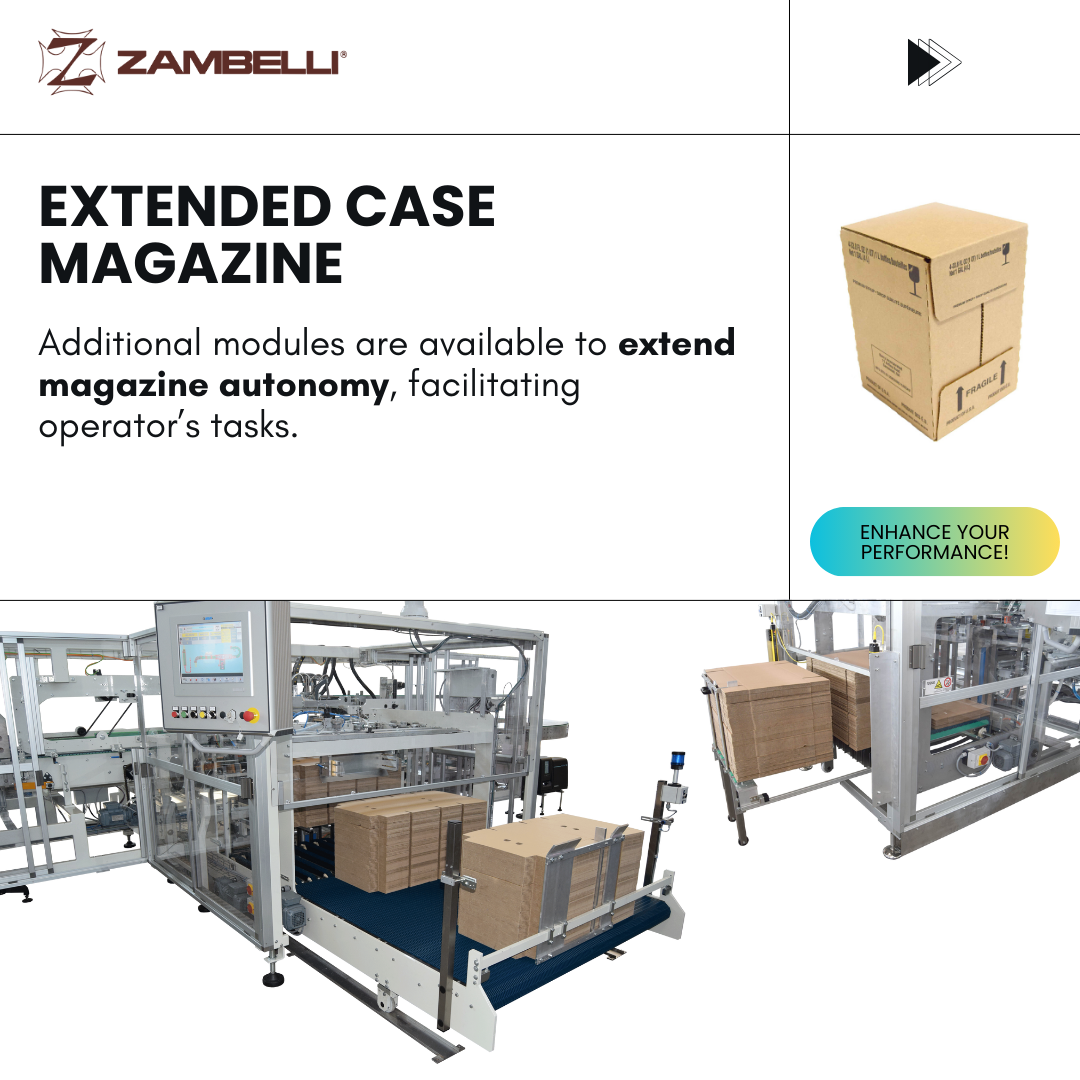

Extended Case Magazine

Additional modules are available to extend magazine autonomy, facilitating operator’s tasks.

Automatic Format Change-Over

In the standard version, format changes must be carried out by the operator.

With the optional automatic change-over all the adjustments otherwise carried out by handwheels are operated by servomotors instead, reducing changeover time and eliminating risk of inaccurate set-ups.

Automatic Lubrication

The standard machine version already has lubrication points connected in clusters to ease maintenance tasks.

The optional version includes a PLC-controlled pump that performs programmable lubrication without maintenance personnel’s intervention.

These premium features are designed to maximize the efficiency and ease of use of our case packers, enhancing productivity and smooth running.

Enhance your packaging efficiency!

Let us assist you in selecting the best Case Packer for your production line.

Request a free consultation now and take the first step towards optimized packaging!