Step-by-step guide to selecting the best case packer for secondary packaging

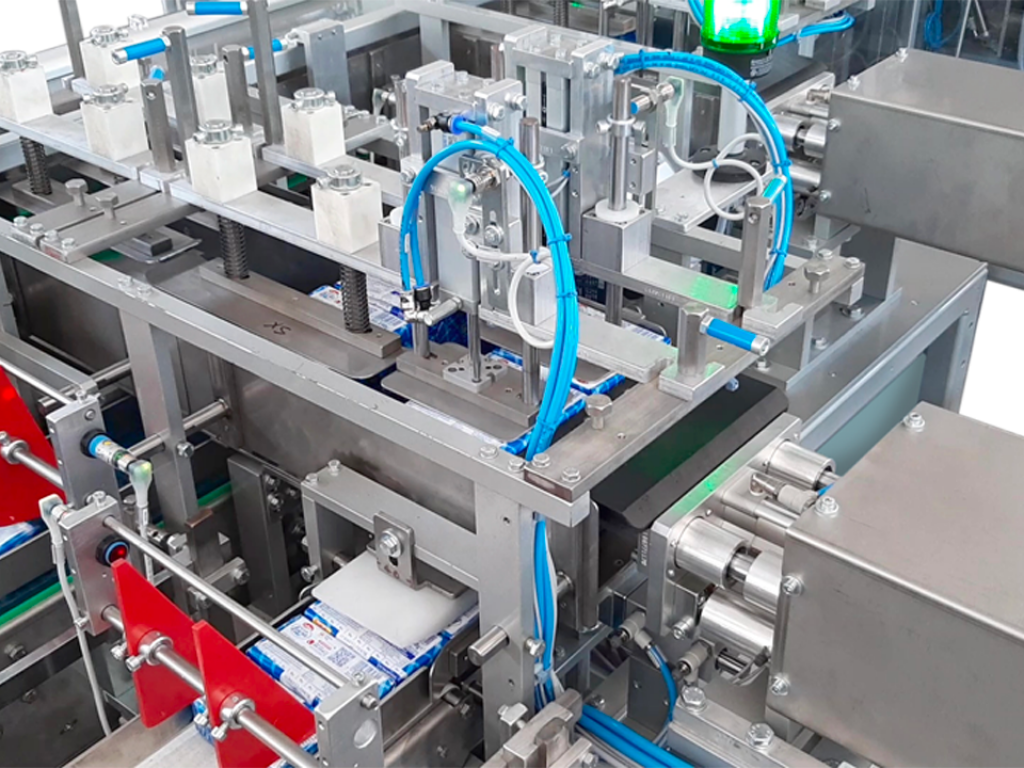

The right case packer is essential not only to ensure product safety and integrity, but also to optimize industrial production processes. It allows different primary packaging formats to be packed into secondary cartons - wrap-around or RSC - providing additional protection and facilitating transportation and distribution. The case packer is a key tool in this process, automating the case packing operation and ensuring accuracy and efficiency, but how to choose the right one?

Factors to consider before selecting a cartoner

Before selecting a cartoner, it is important to evaluate the specific needs of your secondary packaging process. There are several factors that influence this decision, each with the potential to significantly impact production efficiency and final package quality:

- Product type: fragile products require gentle handling, while more robust products can withstand faster, less delicate processes. In addition, the nature of the product (solid, liquid, powder, etc.) will influence the choice of the most appropriate case packer.

- The production speed that the machine must support: the machine selected should integrate smoothly and contribute to the smooth and continuous production of the entire production line. In other words, the machine should not slow down the rest due to its limited capacity or lower efficiency.

- Package size and shape: different machines are suitable for different sizes and shapes. It is important that the case packer can handle the specifications of your product while ensuring that the packaging is protected and presentable.

- Flexibility and adaptability: the market is constantly changing and so are packaging needs. An adaptable case packer that can easily switch between different types of packaging or be upgraded for new formats is an investment in the future.

- Energy efficiency and sustainability: environmental concerns are becoming an increasingly important factor in business decisions. Energy-efficient machines not only reduce operating costs, but also contribute to a more responsible corporate image.

- Budget: set an appropriate budget for the purchase of the cartoner. Consider the initial cost of the machine, as well as the long-term maintenance and operating costs. Analyze the return on investment (ROI) you can expect from purchasing the cartoner. Evaluate whether the expected benefits outweigh the costs associated with purchasing and operating the machine.

Determining each of these variables will help you determine the technical features you need in the cartoner.

Intermittent or continuous motion case packers?

Case packers are not all the same: they can be classified, for example, as intermittent motion or continuous motion case packers. The choice between one or the other depends on several specific factors and the requirements of your production line, product type, and operational preferences.

Here is an overview of the benefits and situations where each type of machine may be best suited:

Intermittent motion case packer:

Intermittent motion case packers offer greater flexibility for different package sizes and formats, making them a versatile choice. They are generally ideal for:

- Low or medium volume production.

- Products that require special attention or positioning.

- Operations that require frequent changes in package size or type.

Continuous motion case packers:

Designed for high speed and high efficiency, continuous motion case packers can handle high production volumes without interruption, reducing downtime and increasing overall productivity.

They are ideal for:

- High volume and high speed production lines.

- Standardized products that do not require complex positioning.

- Operations where speed and efficiency are a priority.

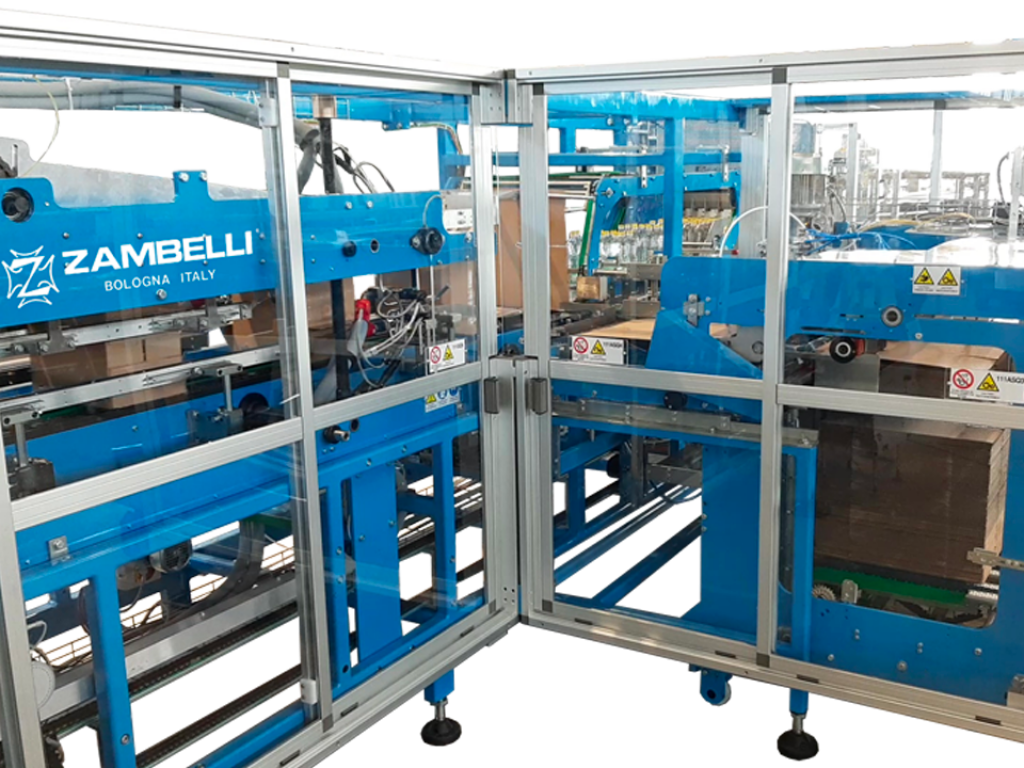

Zambelli's automatic case packing solutions

At Zambelli, we stand out for our customized adaptable solutions in the secondary packaging sector: our machines are designed to perfectly fit your industry and your primary packaging, ensuring unparalleled production efficiency. For more than 50 years, we have been listening to our customers' needs to provide them with the best cartoning machines and the best support and service, from purchase to after-sales.

If you are looking for a reliable and safe partner, contact us! We are here to listen and work with you to find the perfect solution.