The Crucial Role of Primary, Secondary and Tertiary Packaging

Packaging is more than just an aesthetic choice; it's an essential element for protecting, promoting, and delivering a product to its final user.

In this article, we will closely examine the three main categories of packaging: primary, secondary, and tertiary. Each category plays a distinctive role along the supply chain and deserves special attention to fully understand its impact and importance.

Primary Packaging: The Heart of the Product and the First Impression

Primary packaging is the first point of contact between the consumer and the product. It's the milk bottle in the fridge, the blister pack of medicine on the bedside table, or the bag of one's favorite kibble from one's pet.

But its role goes beyond appearance.

Not only does it protect the product from contamination and keep it fresh, but the primary packaging also serves as a vehicle for crucial information, such as ingredients and expiration date. Additionally, its design is a showcase for the brand, capturing attention and communicating its value to the consumer.

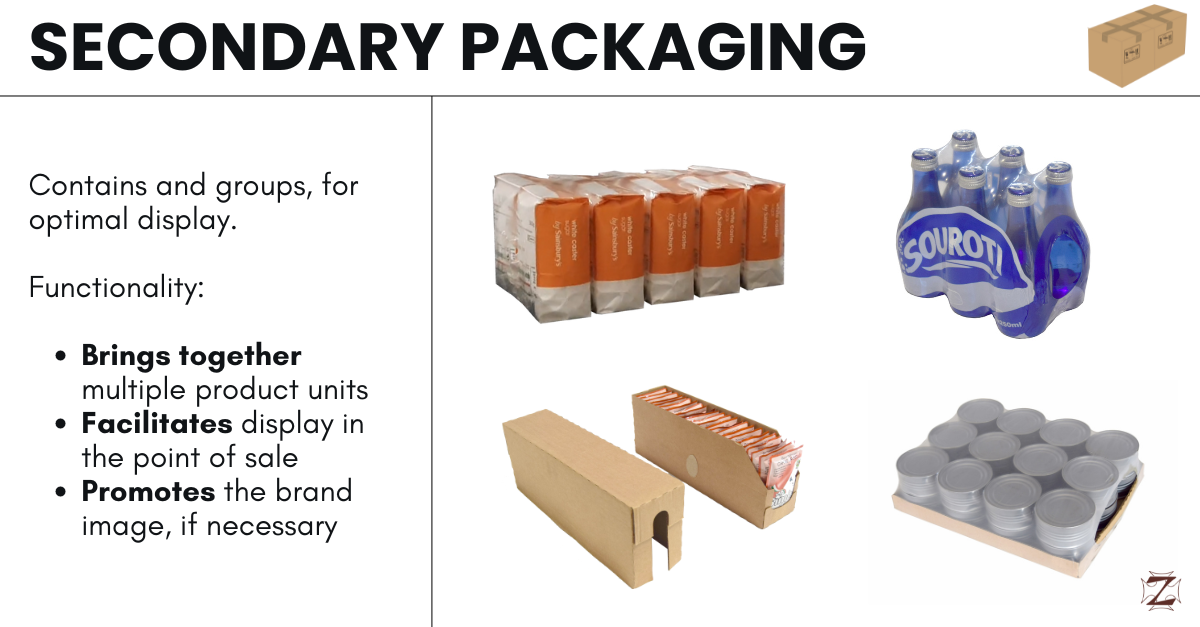

Secondary Packaging: Union and Protection for Secure Delivery

Secondary packaging is the guardian of primary packaging, because it brings together multiple product units to ensure their safety during transportation and to facilitate handling on store shelves.

Although it never comes into direct contact with the product, its presence is crucial to ensure that goods reach the consumer intact and damage-free. Additionally, it provides additional space for brand promotion and product identification, thus contributing to its visibility and recognizability.

Tertiary Packaging: The Invisible Soul of Logistics

If secondary packaging is the guardian of the product in the point of sale, tertiary packaging is its guardian during transportation.

Protective and practical, thanks to its conformation - a pallet as a base, the secondary packages stacked in a stable and calibrated manner, and the roll-up film that keeps them together and compact - the tertiary packaging is essential for the efficient movement of goods and to ensure that they reach their final destination smoothly.

The purpose of tertiary packaging is to ensure easy and safe handling throughout the distribution chain.

Zambelli Packaging: Automatic Machines for Secondary Packaging

Since 1969, we build automatic machines for secondary packaging in the Food & Beverage, Pet Food, and Industrial products sectors.

In our portfolio, we offer shrink wrappers, cartoners, case packers, and integrable robotic systems for every plant; we also collaborate with business partners to supply palletizers.